14 Terms

14 TermsHome > Industry/Domain > Metals; Materials science > Metallurgy

Metallurgy

Metal works and production.

Industry: Metals; Materials science

Add a new termContributors in Metallurgy

Metallurgy

Cyaniding

Materials science; Metallurgy

In this process,the parts to be heat treated are immersed in a liquid bath at 800 to 960 degree of NaCN with the concentration varying between 25 and 90 percent.

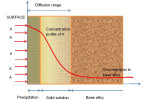

Carbonitriding

Materials science; Metallurgy

This process is specifically used for improving wear resistance of mild,plain carbon or very low alloy steels.Carbonitriding is carried out at low temperatures in the range 800 to 870 degree in a gas ...

Nitriding

Materials science; Metallurgy

Nitriding is most effective for those alloy steels which contain stable nitride forming elements such as aluminum,chromium,molybdenum,vanadium and tungsten.Nitriding is carried out in a ferritic ...

Bronizing

Materials science; Metallurgy

Bronizing is one of the recent methods of surface hardening,which may be applied to any ferrous material but is generally adopted for carbon steel and tool steel.

Chromizing

Materials science; Metallurgy

Chromizing is also used for surface hardening of both carbon and tool steels.The components to be chromized are packed with fine chromium powder and additives.

Wrought Steels

Materials science; Metallurgy

Wrought steels are shaped by plastic deformation(mechanical working).View examples of the ornamental wrought iron railings, fences, gates, spiral staircases .This name of steel is given on the base ...

Cast Steels

Materials science; Metallurgy

Steels shaped by casting method are known as cast steels.Mechanical properties of cast product are inferior as compared to wrought product of same steel.Two important factors,i.e.production of ...

Featured blossaries

Sanket0510

0

Terms

22

Blossaries

25

Followers

Hostile Takeovers and Defense Strategies

12 Terms

12 Terms