10 Terms

10 TermsHome > Industry/Domain > Metals; Materials science > Metallurgy

Metallurgy

Metal works and production.

Industry: Metals; Materials science

Add a new termContributors in Metallurgy

Metallurgy

Martempering

Materials science; Metallurgy

Martempering involve heating the steal to the austenitizing temperature, followed by quenching in a constant temperature bath maintained above Ms point and the usual temperature of bath lies between ...

Process Annealing

Materials science; Metallurgy

In this treatment,steel is heated to a temperature below the lower critical temperature,and is held at this temperature for sufficient time and then cooled.

Spheroidizing

Materials science; Metallurgy

Spheroidizing is a heat treatment process which results in a structure consisting of globules or spheroids of carbide in matrix of ferrite.

Normalizing

Materials science; Metallurgy

Normalizing is a process of heating steel to about 40 to 50 degree above upper critical temperature,holding for proper time,and then cooling in still air or at room temperature.

Hardening

Materials science; Metallurgy

Hardening treatment consists of heating to hardening temperature,holding at that temperature followed by rapid cooling such as quenching in water,oil or salt baths.

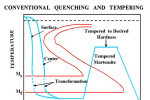

Tempering

Materials science; Metallurgy

A process,which consists of heating hardened steel below the lower critical temperature,followed by cooling in air or at any desired rate,is known as tempering.

Quenchants

Materials science; Metallurgy

A medium that is used for quenching is known as quenchants.The most commonly quenchants are water,oil,salts,air,gases and aqueous solutions.

Featured blossaries

Sanket0510

0

Terms

22

Blossaries

25

Followers

Badminton; Know your sport

23 Terms

23 Terms