10 Terms

10 TermsHome > Industry/Domain > Manufacturing > Plastic injection molding

Plastic injection molding

Plastic injection molding is the primary process for manufacturing plastic parts used in consumer goods such as computer keyboards, monitors, bottle caps, cups and solid plastic articles. Plastic is known to be a very versatile and economical material that is used in many applications. Injection molding involves taking plastic in the form of pellets or granules and heating this material until a melt is obtained. Then the melt is forced into a split-die chamber/mold where it is allowed to "cool" into the desired shape. The mold is then opened and the part is ejected, at which time the cycle is repeated.

Industry: Manufacturing

Add a new termContributors in Plastic injection molding

Plastic injection molding

sprue bushing

Manufacturing; Plastic injection molding

A hardened-steel insert in the mold that accepts the nozzle and provides an opening for transferring the melt.

mold

Manufacturing; Plastic injection molding

A hollow form or matrix into which a plastic material is placed and which imparts to the material its final shape as a finished article.

crystal

Manufacturing; Plastic injection molding

A homogeneous solid having an orderly and repetitive three-dimensional arrangement of its atoms.

isobar

Manufacturing; Plastic injection molding

a line of equal pressure. Any point along an isobar sees the same cavity pressure as any other point along the same isobar.

isotherm

Manufacturing; Plastic injection molding

a line of equal temperature. Any point along an isotherm is at the same temperature as any other point along the same isotherm.

isochrone

Manufacturing; Plastic injection molding

a line of equal time. Any point along an isochrone is filled at the same time as any other point along the same isochrone.

release agent

Manufacturing; Plastic injection molding

a material sprayed on the mold which facilitates removing the part.

Featured blossaries

stanley soerianto

0

Terms

107

Blossaries

6

Followers

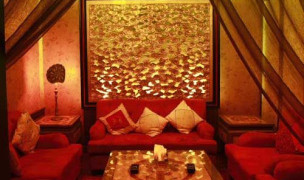

Top 10 Best Nightclubs In Beijing

10 Terms

10 Terms